When it comes to a car’s critical systems, the one that makes you stop might just be the most important. Anyone that has experienced the sheer terror of brake failure will likely agree, as the joy of driving dissolves when your safety relies on you steering your beloved vehicle into the softest thing in sight. The first step to working on brakes is understanding how they work. Here are seven brake system terms to get you started on the basics.

Drum brakes

All brakes involve turning kinetic energy into heat, by way of friction. The controlled application of friction is designed to slow down and ultimately stop your vehicle. Drum brakes are the most common type of brakes on vintage and classic cars. The concept is simple: a metal “drum” is mounted to the wheel studs, and brake shoes coated with friction material are forced outward on the interior of the drum. What you see above is the common internal-expanding design, but there are external contracting versions that actuate by clamping the friction material to the outside surface of the drum.

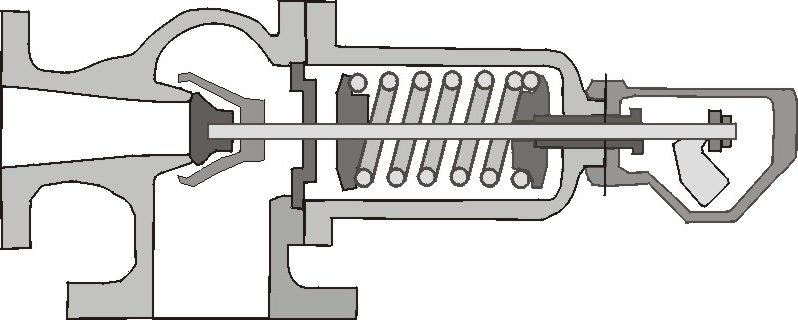

Disc brakes

The more modern system compared to drums, discs are used almost exclusively in today’s cars. In this design, friction material clamps to a disc affixed to the wheel studs. A big advantage over drums is that discs are self adjusting; with no springs returning the friction material to a set position—as with a drum brake system – the calipers that hold the friction material automatically adjust for pad wear. Disc brakes often shed heat more effectively than drums, which means more consistent performance during extreme operating conditions and repeated, hard braking.

Proportioning valve

Under braking, weight naturally transfers to the front of the car. Because of this unequal load, it is not ideal to simply apply equal braking force to each wheel. That is where the proportioning valve comes in; it is essentially a restriction, sometimes adjustable, that regulates how the pressure in a hydraulic brake system is distributed. Some systems do not use a proportioning valve and are instead designed so the pistons of the wheel cylinders are sized to provide proper braking force. All the more reason to fully understand the nuances of your brake system before making changes or modifications.

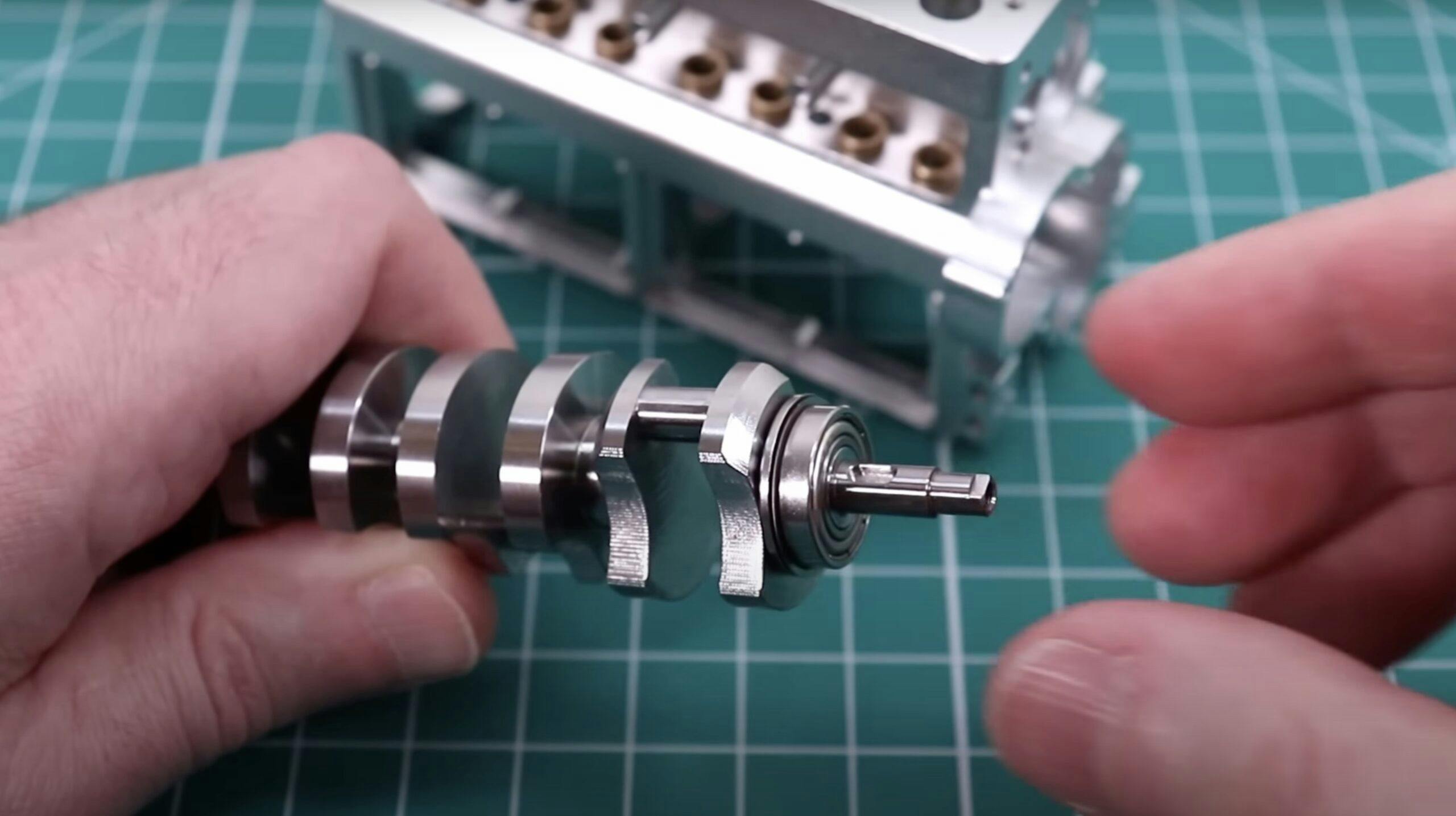

Master cylinder

Pressing the pedal in a hydraulic brake system uses the lever of the pedal to push a piston in the master cylinder. That piston then forces fluid out of ports that are connected to the brake lines running to each braking unit. A reservoir sits on top of the master cylinder to compensate for fluid expansion or system wear.

Wheel cylinder

The wheel cylinder responds to the pressure generated by the master cylinder. The wheel cylinders are mounted to the backing plates of drum brakes to actuate the brake shoes. Pressure transmitted through fluid from the master cylinder pushes on a pair of pistons within the wheel cylinder, forcing the brake shoes out against the brake drum. The wheel cylinder also has the bleeder screw used for removing air from the system.

Hardline vs. softline

Between the master cylinder and the wheel cylinders there is a network of tubing to transfer pressurised brake fluid. Most of the longer-distance runs are done with hard lines, which are typically made of relatively small-diameter metal tubing that will not expand under pressure. These hard lines are joined with flared fittings to reduce the chance of leaking or pressure loss.

Soft lines are useful for shorter-distance runs where flexibility is necessary, such as connecting the brake line from the frame to the wheel cylinder on a car with independent suspension. Rubber lines join to the hard lines and allow movement in the system without risking fracturing a metal line.

Over time, hard lines corrode and soft lines need to be checked for wear. Both are crucial to keep your brakes working safely, and because they are under pressure and generally exposed to the elements, these parts can often corrode and contribute to an MOT failure, or advisory notice.

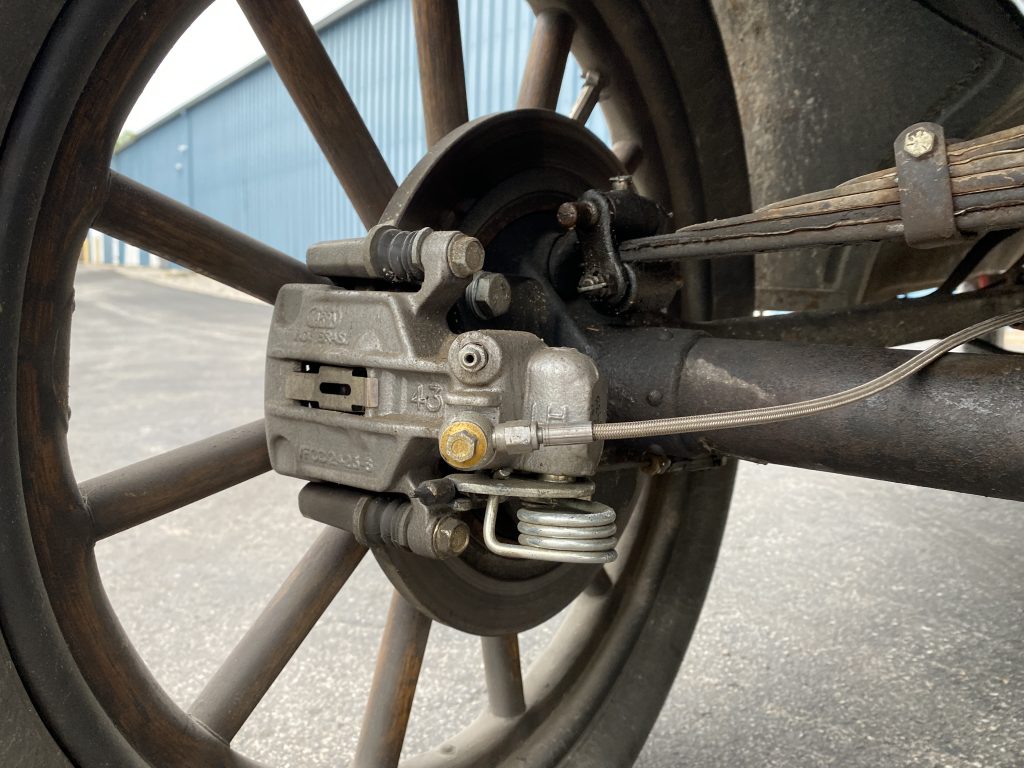

Mechanical brakes

Hydraulic brake systems are the most popular, but some vintage cars have unassisted mechanical systems to actuate the brakes. The Model A Ford is a prime example of a car fitted with mechanical brakes. Rather than relying on fluid to transmit the pressure from pedal to brake shoe, most mechanical systems use rods and pivots. Such systems can still be reliable and safe, but proper setup is key; with an unassisted system there are no fluid dynamics to boost the force between the pedal and the actuator at the wheel.

These are, of course, just the tip of the brake terminology iceberg. Leave a comment below with additional terms you think are important for a novice to know.

Via Hagerty US.