Picture the Tokyo Motor Show during the peak of the Japanese economic bubble in the late 1980s and early 1990s. You’re probably envisioning an auto show filled with optimism, enthusiasm, and innovation: a platform where Japanese automakers continually rolled out groundbreaking sports cars, outlandish designs, and advanced technologies.

You’re probably not picturing big rigs and futuristic concept trucks. That’s understandable, given most media coverage of the Tokyo show didn’t stray from the automotive displays into the commercial vehicles wing. But it’s also a shame, because these concepts were packed with technology decades ahead of their time. For the better part of a decade, Mitsubishi in particular cranked out a series of innovative concept trucks (under the Fuso sub-brand name) that rivalled anything shown in the main hall.

1985 – MT-90X

Mitsubishi’s Fuso truck division kicked things off in 1985, unveiling the MT-90X concept. Billed as the “shape of tomorrow,” Fuso’s first concept truck was clearly based on its line of “The Great” heavy-duty trucks launched two years prior. Only, the MT-90X looked more ready for a run at Bonneville, not an overnight cargo shipment.

While designers extensively tuned the production truck to optimise aerodynamics, the MT-90X took that focus to a new extreme. An integrated air deflector tapered into side fairings at the back of the cab to channel air over and around the aluminium van body behind it. Designers nixed the cab’s grille opening and added argent cladding which wrapped around the perimeter of the truck. The cladding enveloped the front and rear bumpers, chassis skirts, and power cab steps, which rotated out from a flush storage position whenever a door was opened.

Power came from a modified version of Fuso’s 11-litre turbo-diesel six-cylinder, mated to a prototype seven-speed single-clutch automated manual transmission. To help shed weight, the MT-90X rolled on aluminium wheels shod with bespoke low-profile rubber. The tyres featured a tread block designed to reduce rolling resistance. The front suspension used GFRP leaf springs to shed weight, while electronically adjustable dampers were fitted both front and rear.

Inside, designers took advantage of the MT-90X’s elevated roofline and built a plush sleeper cabin packed with plenty of technology, much of it cribbed from Mitsubishi’s electronics division. The driver was greeted not only with a full digital gauge cluster, but also rain-sensing automatic wipers, a screen for a rear-view camera, and a system which monitored the distance between the truck and the vehicle in front of it. The bunk itself was elevated atop a large wall containing a fridge and wardrobe, while a TV, VCR, and a PC system provided the driver with some entertainment after a long day on the road.

As MT-90x’s paint scheme proclaimed, all of its aerodynamic trickery yielded a drag coefficient of 0.38. Considering an regular production “The Great” measured in at 0.56 cD with a standard van body, that’s pretty impressive. It’s still impressive today, especially when Tesla says its super-sleek electric Semi falls somewhere between the 0.36-0.40 cD range.

1989 Advanced Technology Super Fighter

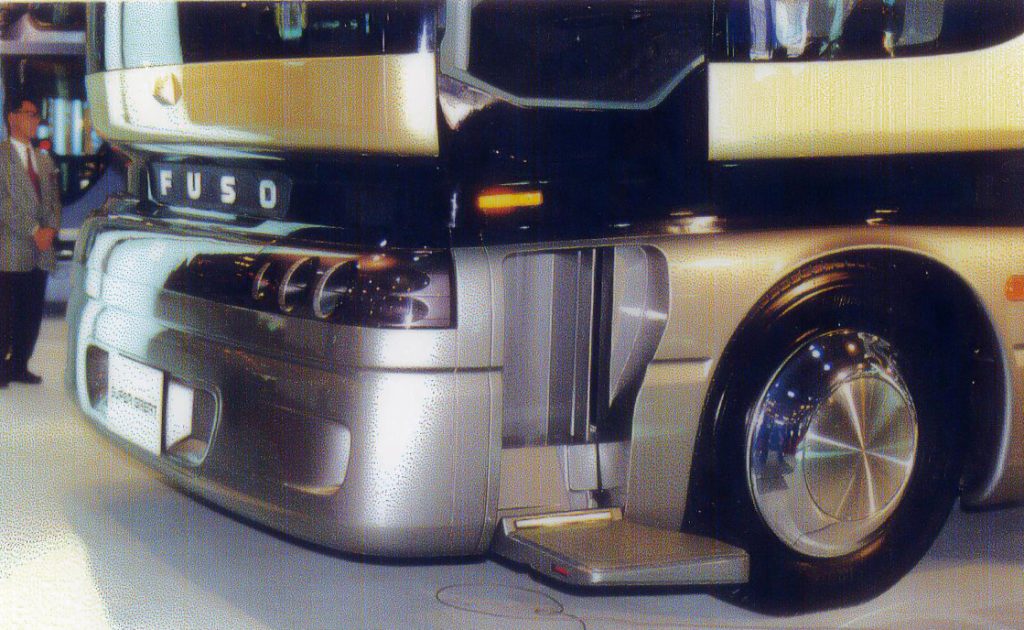

If Fuso played things slightly conservative with the MT-90X, it made up for lost time five years later with the Advanced Technology Super Fighter concept. The show truck may have shared an engine and chassis with Fuso’s production medium-duty truck line, but that’s where the similarities ended. The standard Fighter was a blocky-looking cab-over, while the Super Fighter resembled a tall, streamlined European motorcoach, thanks to a tall roofline dominated by a massive wrap-around windshield. Bodywork was fabricated entirely from lightweight composites, while thin headlamps in the front bumper packed a triad of HID projector lamps, lending the headlamps a slight resemblance to those on an S13-generation Nissan Silvia.

No drag coefficient was publicised, but aero was clearly once again a design priority, given the non-existent gap between Super Fighter’s cab and body, wheels capped with Moon-esque discs, windshield wipers hidden beneath a pop-up panel, and exterior mirrors replaced by cameras at every possible angle.

Unlike MT-90X, Super Fighter left its rear wheels exposed to the world – possibly to help showcase its prototype four-wheel steering system, a technology less likely to be found on a medium-duty truck than Mitsubishi’s own 3000GT sports car. Other technologies ported from the automotive world: a driver’s SRS airbag, traction control, and ABS – the latter of which was prominently displayed during the Super Fighter’s brief cameo in the Jackie Chan film Thunderbolt.

While crowds stared at the gullwing doors and their integrated flip billboards, the Super Fighter’s van body was as functional as it was flashy. Its tailgate neatly integrated a hidden hydraulic lift, while the deck floor’s integrated rollers simplified moving cargo within.

The Super Fighter’s biggest party trick wasn’t how it loaded cargo, but rather how it loaded the driver. Although the passenger’s door opened conventionally, the driver’s door slid forward, allowing an electromechanical arm to extend a Recaro bucket seat down to kerb level. Wicked!

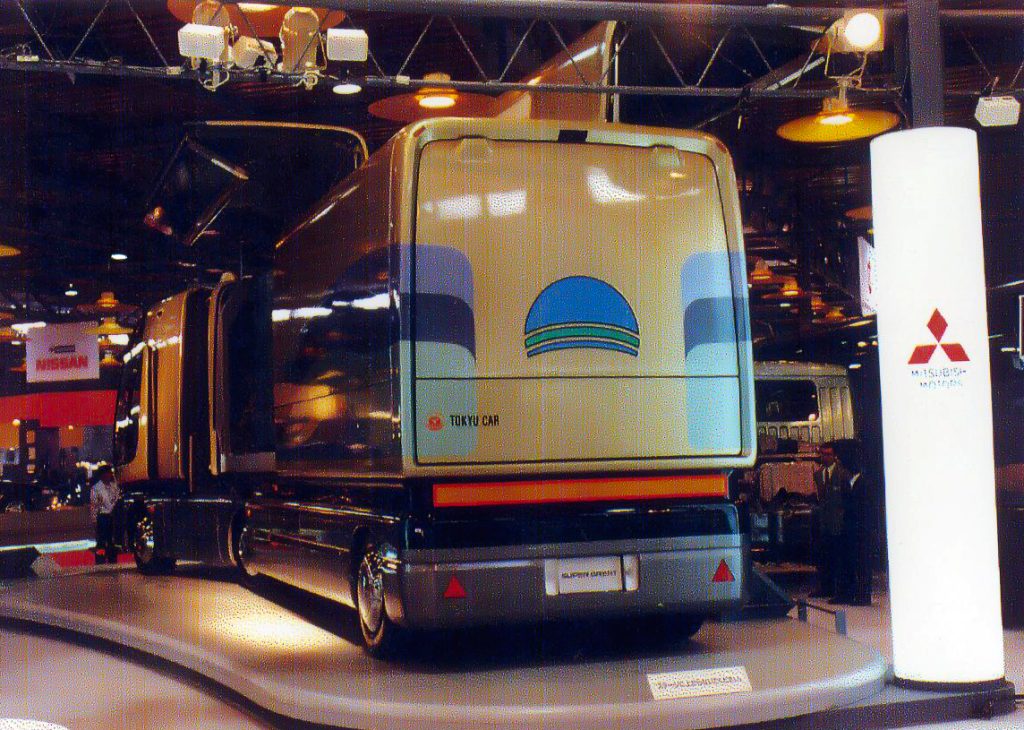

1993 – Advanced Model Super Great

What would happen if you enlarged the Super Fighter on a copy machine? The result might look similar to the Advanced Model Super Great concept, which debuted at the 1993 Tokyo show, sharing a number of design cues – notably its windscreen and window design – with the smaller Super Fighter.

Like Super Fighter, Advanced Technology Super Great employed a number of aerodynamic tricks: Moon disc wheels, cameras in lieu of mirrors, and more – to reduce drag. Windshield wipers still hid beneath a pop-up panel up front, but they were almost redundant, as Super Great’s massive windshield was treated with a hygroscopic fluorinated coating; think of it as a more resilient (and expensive) application of Rain-X. The windshield also featured an embedded liquid crystal layer above the driver’s head, which could be darkened at the push of a button to block glare.

Cab entry and egress was once again automated, but for both driver and passenger this time. After sliding cab doors rearward, step platforms rotated out from the lower body work and served as elevator platforms, lifting occupants feet off the ground.

Inside, the wrap-around cockpit looked fairly conventional compared to production trucks of the time, but it was jam-packed with advanced features – so much so that the push-button shift controls for the truck’s Allison automatic transmission were moved to the armrest of the driver’s Recaro seat. The gauge cluster was offset to make room for three screens directly in front of the driver, providing an effective 360-degree view around the truck.

Not enough screens for you? Fine. A fourth, immediately to the driver’s left, served up GPS navigation menus and other real-time running information. Need to call the home office, or file some paperwork remotely? No problem – the centre console also included a fax machine. A control panel immediately next to the fax controlled a system that allowed the trailer and its air and electrical lines to be coupled or decoupled at the push of a button.

Frustratingly, Fuso kept many technical details of the Super Great, including its powertrain and drag coefficient, close to its vest, opting to instead focus on other technologies shown on the truck. ABS (and traction control) were once again included, as was Fuso’s prototype four-wheel steering system. A hydraulic active suspension on the tractor itself worked to mitigate body roll and vibrations transmitted through the trailer.

One of the more unusual features on Super Great: a drowsiness detection system, which monitored the driver’s alertness. Did it provide audio, visual, and haptic warnings if it feared the driver was nodding off, like similar systems do today? Yep, but it also worked with the HVAC system to increase the oxygen concentration within the cab in the hopes of improving alertness. Bonkers.

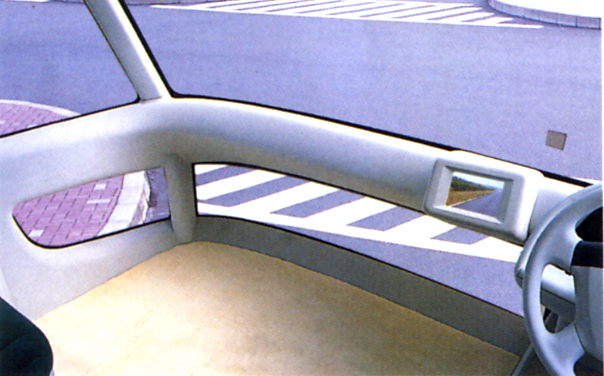

1995 Advanced Technology Super Great X

Two years later, Fuso returned to the Tokyo show with an all-new tractor-trailer concept … or did it? While it appears the Super Great’s trailer may have been repainted and recycled, the new Advanced Technology Super Great-X’s tractor was a clean-sheet design.

The cab’s design was dominated by a split-level wrap-around windshield, which was also the only bit of daylight opening in the design. The lower front fascia again incorporated HID lights but in a new “black mask” graphic, emulating a grille while hiding a taller bumper that included an underride beam to protect passenger vehicles in a collision. Wipers were still hidden, mirrors were still replaced by cameras, wheels were still capped with discs, but this time around Fuso was willing to discuss drag. Super Great-X measured in at 0.34 cD, marking a continued improvement from its first aerodynamic truck experiment a decade prior.

Perhaps the biggest change was Fuso’s approach to interior packaging, which was immediately apparent after climbing the pop-out staircase and ducking beneath the cab’s bi-folding gullwing door. Super Great-X provided occupants with open space, and lots of it. There was no engine doghouse, no centre console, or even a full-width dashboard. There was merely a flat floor, a tall ceiling, and two seats. A sleeping berth folded out from the rear wall, while a personal computer unfolded from the back of the passenger seat.

The driver’s station was remarkably simple, consisting mainly of a large gauge cluster flanked by a pair of screens, again serving as mirrors. The digital gauge cluster included another screen, which could either display camera feeds from outside the truck or allow the driver to display GPS maps, performance data, or configure settings through a controller in the seat’s armrest. The lack of a full-width dashboard also provided the driver with a great view of surrounding traffic and pedestrians, but only to a certain speed. Reflecting concerns the driver might be overstimulated and grow fatigued during longer slogs down the highway, the lower windshield panel turned opaque at speeds over 35 mph.

Predictably, there was plenty of advanced tech to be found in addition to the last concept’s active suspension and automatic trailer coupler. Fuso built upon the distance warning system it’d been showing off for a decade by tying it to Super Great-X’s cruise control, adjusting the set speed to maintain distance from the vehicle ahead. Super Great-X also marked Fuso’s first attempt at fitting a driver’s airbag to a heavy-duty truck, let alone a tractor-trailer.

Super Great-X’s interior packaging is even more impressive considering a massive 21-litre diesel V8 lurked underneath, cranking out 415 hp and just under 1100 lb-ft of torque. The engine was also paired with a prototype diesel particulate filter (DPF), which helped strip soot from the exhaust stream.

Where Are They Now?

As much as we’d love to tell you these futuristic Fusos are squirrelled away in a corner of the company’s proving grounds with the rest of its historic vehicle collection, that’s not the case. Fuso reps confirm these trucks no longer exist, although a MT-90X wind tunnel model recently surfaced at a rather eclectic transportation museum in Chiba prefecture, and you’re welcome to print and build your own scale replicas for your own bookshelf with these papercraft models.

Fuso’s concepts may not live on, but much of their ideology and technology certainly does. We may not be loading cargo into gullwing trailers (at least not in America), nor are truckers ascending to their cabins on elevators or retractable Recaros, but many of the features and technologies that were outlandish thirty years ago are either common today or, as in the case of camera-based mirrors, still in the process of arriving to market. DPF systems came into commercial reality in the late 2000’s. Under-chassis fairings and sail panels, like those used on the MT-90X, are a common sight on interstate highways. Multi-function screens and advanced connectivity are all but expected in modern trucks. And while driver’s airbags aren’t mandated on heavy-duty trucks in North America, they are still available in many Class 8 trucks. Indeed, today’s haulers owe much to Mitsubishi’s vision.