Given this week’s news that Jaguar will cease selling cars in the UK for two years, it’s hard not to feel sadness. After kissing goodbye to the XE, XF, and F-Type over the past year, it culled the E-Pace SUV and I-Pace EV in July, leaving only the F-Pace to hold the fort until a new wave of EV models appear for 2026.

This means that there is no traditional Jaguar saloon left – the replacement XJ was ditched a matter of months prior to launch several years ago. A huge shame; after all, while the E-Type and other sports cars might hog the headlines, it was the XJ line that exemplified the true essence of Jaguar for most people.

They were refined, elegant, comfortable, and blessed with good handling – and not just for an executive car, but good handling, full stop. Though the straight-sixes and, later, the V8s, did much of the heavy lifting in the sales department, the absolute pick of the range had to be the XJ12, or if you’d had a good year in the eyes of the shareholders, a Daimler Double Six.

At the heart of it all, of course, was the Jaguar V12 engine. First developed as a possible Le Mans car powerplant in the early 1950s by Claude Bailey, its development would continue far beyond Jaguar’s 1957 withdrawal from racing. In 1962, Bailey was given the go ahead to start honing the V12 still further with an eye on production and racing.

The racing car that would have taken the V12, the XJ13, would be cancelled, but by 1964 prototype engines were being tested in Mark X saloons. Though the sight and sound of a screaming V12-powered XJ13 taking the fight to Ford and Ferrari at Le Mans was denied to us, it did add extra emphasis to the road-car development programme.

Under the supervision of Walter Hassan and Harry Mundy, a new single-overhead-camshaft cylinder head was developed. In a similar fashion to the Rover 2000 at the time, the camshaft lobes acted directly on vertically inclined valves via bucket tappets. Like the Rover, the V12 used dished Heron-style pistons that helped to simplify construction yet also reduce weight, size, and noise.

The new cylinder head did rob the engine of power at the top end, but the engineers fought back by increasing displacement to 5.3 litres, which boosted low-to-mid-range torque. Indeed, take a look at a contemporary Mercedes-Benz W116 S-Class, launched the same year as the 250bhp V12 Jaguar XJ – in peak 450 SE/L form, its 4.5-litre V8 could only muster 278lbft. The Series I XJ12 doled out a chunky 301lbft. Mercedes-Benz would have to develop the mighty 450 SEL 6.9, launched in 1975, to best the Jaguar V12.

Series I (1971–72)

The Series I XJ12 debuted three years after the launch of the first XJ; at the time, it used four sidedraught Zenith-Stromberg carburettors, though it could have been very different. The original plan was to use an AE Brico-developed fuel-injection system, but it was cancelled at the last moment. Nevertheless, the car had two bragging rights: Not only was it the only mass-produced 12-cylinder road car in the world, its 140mph top speed made it the fastest four-seater in the world.

In 1973, Jaguar revived the Daimler name to represent the very highest level of luxury; by the time the Series 2 XJ appeared that year, 4113 V12-powered XJs and Double Sixes had found homes.

Series II (1973–79)

The Series II model broke cover in autumn of 1973, with a more rounded shape, raised front bumpers, and a smaller front grille to satiate the needs of US crash safety regulations. Inside, the interior was revamped with simpler and more efficient heating and air-conditioning systems.

In 1977, the Borg-Warner automatic gearbox was replaced by a General Motors Turbo-Hydramatic 400, and a year later the carb set-up was replaced with Bosch-Lucas D-Jetronic fuel injection. This took horsepower up to 285bhp from 258bhp, though torque fell to 294lbft. By the time Series II production came to an end, Jaguar had sold 14,226 V12 models.

During this time, Jaguar also produced 2262 two-door XJ and Daimler Double Six coupés. Despite being revealed to the world at the London Motor Show in October 1973, the oil crisis of that year meant it would only see showrooms from 1975. By that point, the new XJ-S was on sale, and thanks to higher costs courtesy of the complex build process, the car was not quite as popular as it could have been. Production of the coupés would cease in 1978, a year before it ended for the four-doors.

Series III (1979–92)

Jaguar turned to Pininfarina to spruce up the XJ12 and Daimler Double Six for the new decade. Combining the talents of Leonardo Fioravanti and Lorenzo Ramaciotti, more famous for their Ferrari designs, the duo incorporated thicker rubber bumpers, one-piece front door glass, and revised the roofline for a larger glass area and narrower door frames.

Under the skin, the V12 would remain the same until 1981, when the HE (high efficiency) model was launched. Swiss racing driver Michael May had made a name for himself with fuel injection projects for Porsche and Ferrari, as well as turbocharging Ford V6s. His design for the Jaguar V12 saw the addition of a swirl chamber at the exhaust valve, with a channel around the intake sleeve. Another revision saw the introduction of more traditional flat-topped pistons, which via stratified charge allowed the engine to run a high compression ratio for the time while using a lean fuel mixture. Though this didn’t add much by way of performance, it improved fuel economy by as much as 50 per cent. At the same time, a digital ECU with an integrated manifold air pressure transducer was installed (the Digital P system).

During the Series III’s tenure, the Jaguar XJ40 was enduring a long and difficult gestation period; work had begun in the early 1970s, and the car wouldn’t launch until 1986. This was only really made possible by the Series III’s resurgence in sales, particularly in the USA – Jaguar CEO John Egan took this as an opportunity to further refine the XJ40. The Series III soldiered on until 1992, with 10,500 V12 models sold.

XJ40 (1993–94)

According to legend, the XJ40 was specifically engineered to prevent V-configuration engines from fitting, because at the time, British Leyland had expressed an interest in using the Buick/Rover V8, much to Jaguar staffers’ disgust.

As such, the XJ12 was allowed to carry on until 1992, with the XJ40 only receiving a V12 engine in 1993. Allegedly, when Ford saw the state of the project (which was supposed to have been launched in 1990), it instigated a fresh start on the whole project. The process had taken an extensive redesign of the front of the car, at a cost of £35M. More than 140 new or modified panels were deemed necessary, and Jaguar took the opportunity to fit the new 6.0-litre engine, which had been introduced in the XJR-S in 1989. The engine was stroked to 78.5mm, which took power to 318bhp and a meaty 336lbft of torque.

Unfortunately, the market simply didn’t take to the new car – having sold 6000 Series III V12s in 1991 alone, Jaguar shifted just 3799 in 19 months. Though the worldwide recession played a part, the engine was beginning to show its age against newer, more refined and more economical German V12 rivals, and the XJ40 design language was, by now, at least a generation behind the 7 Series and S-Class.

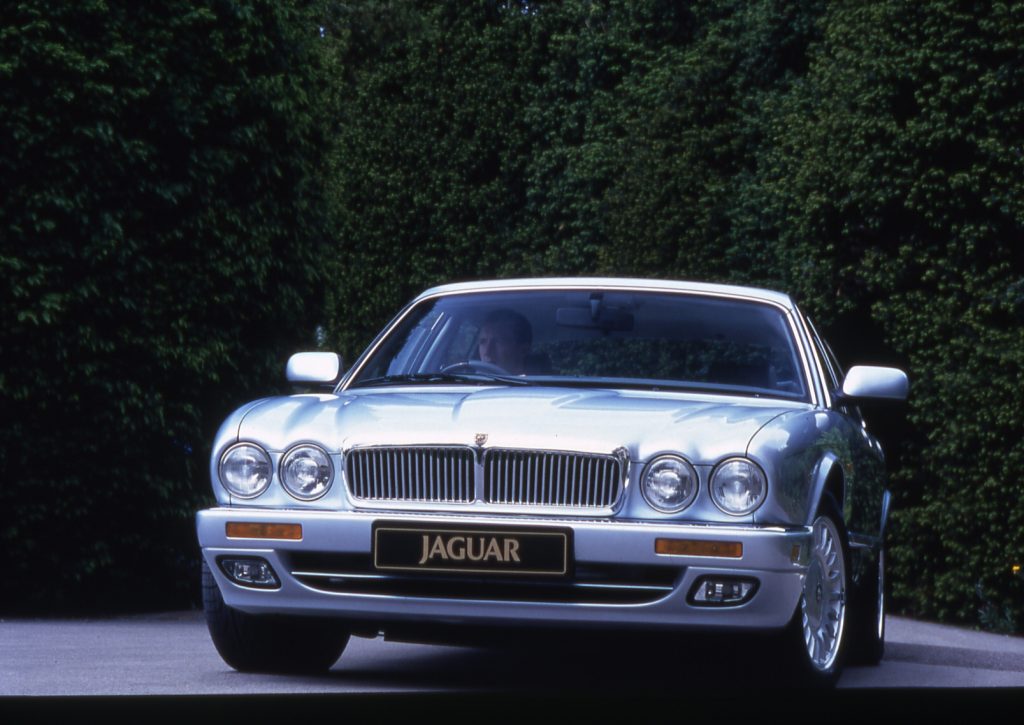

X305 (1994–97)

The X300 was a great leap forward for Jaguar. Even though its Geoff Lawson design was intentionally retro-themed compared to the sharper-edged XJ40, the car was built in an ultra-modern way: Nissan-sourced automated body-welding robots. The wider story of the X300 is more nuanced – the first new car introduced under Ford control, it came about due to the discontinuation of the XJ90 saloon project. While that entire car was cancelled, Ford decreed that its front and rear ends be placed onto the centre section of the XJ40, allowing for a new V8 to be used.

In the end, that V8 wouldn’t make its debut until much later. In the meantime, the six-cylinder and V12 continued on. The V12 model, known as the X305, was a further development of the XJ40’s 6.0-litre, and used a Nippondenso distributor-less crank-fired ignition system with coil packs.

It would be the final fling – quite simply, the new V8 models coming through for the X308 were lighter, more efficient and, while not quite as smooth, rather more potent. The very last V12 XJ was a green long-wheelbase model, which you can see at the Jaguar Collection at the British Motor Museum at Gaydon. Just 3158 V12 X305s were made.

Final Thoughts

The V12 XJ was a byword for smoothness, yet it was a torquey unit that even until the 1990s could run with the German pack in terms of performance. An EV Jaguar might offer even more torque and, due to the silence of an EV powertrain, even more smoothness, but there’s a delightful mechanical joy to Jaguar’s V12.

With more people working from home, this means a V12 XJ makes great sense as a semi-daily driver – we even blanche at the idea of using one as an everyday commuter, thanks to the fuel consumption. But put it this way: How would you rather arrive, silently in a formless EV, or purring to a stop in one of the greatest saloon cars ever made?

Always amazing, in the XJ-S, just how smooth the V12 engine is and then you realise it started it’s development in the 1950s. The smoothness and power is a potent combination.

I just love my XJ-S. You look after it, it looks after you. Wonderful engine and the road holding still sensational.

I used both a 1985 and then a 1990 XJ-S as daily drivers between 1990 and about 2002. Both purchased used and both dead reliable. They never let me down and were a joy to drive. It always seemed a shame that the XJ-S never received the recognition it deserved in the US. To my benefit however, that made them more affordable. My wife took the 1990 long distance to a business conference at one point and when she returned she said, “You’re right! You get it up over 100 MPH and it settles down and just begs to go faster!” I might mention that the 1990 also competed successfully in the JCNA driven class Concours.

I have owned 3jags and loved all of them what a disgrace to turn them lnto glorified scaletrics what a joke having a load of weirdos advertising what was once a great car brand