Motorsport is not for the faint of heart, mind, or wallet. Even at the lower tiers, it is easy (if not incredibly difficult) to watch thousands of dollars vapourise in an instant. Recovery time from such events does not get easier when you add more people, more money, and more speed. Case in point: the Williams Racing Formula 1 team recently documented the process of getting its two massively wrecked cars ready for the track again after the Sao Paulo Grand Prix.

The Brazilian race was a smorgasbord of conditions, with interesting twists underlying the action. Unfortunately, those conditions led to crashes that contributed to a few of the interesting twists, and both of the Williams FW46 machines were brought back to the paddock on a flatbed. Williams’ Argentine driver Franco Colapinto was first to have an off when the back of the car stepped out during qualifying. Englishman Alex Albon unfortunately had a similar experience, and what a site it was to see both cars being hoisted off the recovery trucks into the pitboxes.

Each car was in rough shape and the team took a full two hours of its limited repair time to assess and make a plan for the fixes. The team concluded there was no way to get Albon’s car back into shape for the race and focused instead on Colapinto’s chassis. Rebuilding any car overnight is impressive. Rebuilding one as complicated as an F1 car and still making the grid for the race is truly something else.

Unfortunately, effort and luck are occasionally inversely proportionate. Such was the case for the team when Colapinto hydroplaned on lap 32 of the race and found himself colliding with a wall again. So Williams packed up and shipped the cars off to its Grove HQ, and luckily there was a camera crew there to capture some of the process that went into returning the cars to track-readiness.

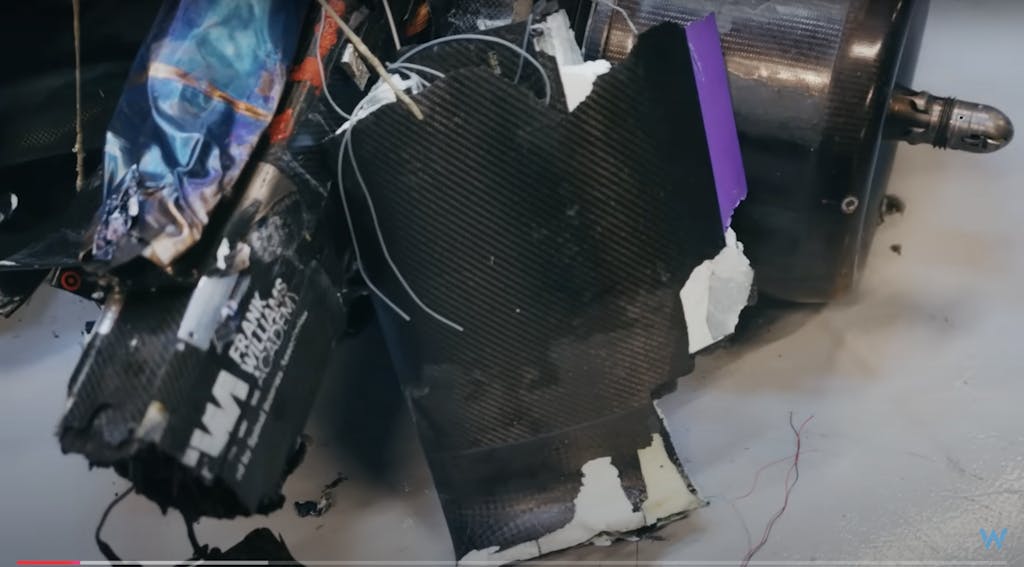

What remained of the cars arrived by air freight in boxes, carried into the pristine shop by forklifts, where a horde of anxious hands immediately began sorting everything. Even as they picked through splinters of carbon fibre and mangled exhaust pipes, it was interesting to see the team still joking a bit and smiling. They might be tasked with coming in for an overnight shift to put together a race car, but they aren’t going to let it get them down—even as they filled an entire pallet bin with very expensive-looking scrap.

It was interesting to see just how thoroughly inspected even the scrapped parts were. Anything that could be reused certainly would be, and that philosophy goes all the way down to the metallic inserts that hold body panels together and wiring in place. It’s the “pennies” of these small parts that add up and are critical in saving real dollars for a small-budget operation like Williams. Some of those parts might be make or break for getting to the end of the season. The setup of the car could potentially change based on what spares are available, meaning with each crash the car could actually become less ideal. It’s a fascinating challenge to face as a team.

Regardless, in just one week’s time, the Williams team turned a broken chassis in a grid-ready car that we will see rolling into a garage in Las Vegas very soon. The tools used and processes implemented to take apart a race car aren’t so different from the way you and I would do it, so while the technicians might have a well-lit and spotless shop to work in with perfectly organised tools, it was the hands and minds of the techs who restored the car. It is the human effort that makes the spectacle of the race happen, and the rebuild process is a prime reminder of that.