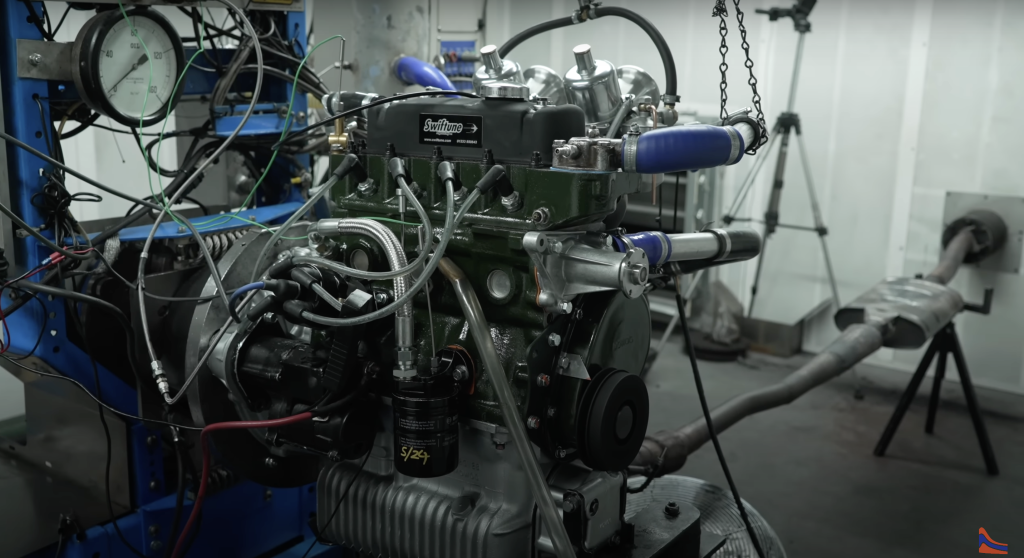

Going fast is a relative thing. Vintage Minis are known for being quick in the corners, but some are quick on the straights as well thanks to engines from veteran builders like Nick Swift of Swiftune in Kent. When turning up the wick for racing, every engine has its own needs and wants, and Nick was kind enough to share some of his tips and tricks for the BMC A-Series in a YouTube video for Alex Brundle.

Since Swiftune builds racing engines, the rulebook governs what he can and cannot do. To race in FIA-sanctioned competitions with other spec-built vintage Minis, both the cylinder head and engine block of this inline-four need to be original equipment or reproductions done to the OE standard. That requirement keeps the packaging the same, but what’s inside that block and head is a lot less limited. There, a builder like Swift can incorporate a lot of new tech, all of it aimed at two goals: durability and power.

The rotating assembly of the engine Swift walks us through in this video is a replacement, OEM-style crankshaft with H-beam connecting rods and relatively simple-looking aluminium pistons. Keeping the factory cylinder head design prevents Swift from using a wild combustion chamber shape, so the slugs, which are only slightly dished, make sense; heavy valve reliefs or attempts to raise compression significantly are not needed. Swift even notes that his Mini engines stay close to stock displacement, since he only bores .020 of an inch past stock on the re-lined cylinders. This decision makes for a very strong core of the engine and allows for more rpm, and that is where the power comes in.

The valvetrain decides the airflow of an engine, and since engines are air pumps, a builder is wise to focus a fair amount of time and energy on making sure the air and fuel flow easily. For Swift and the A-Series, the start of that process is a custom camshaft that optimises when the valves open and close. Up top, the valvetrain uses shaft-mounted rockers and traditional pushrods. Those may not seem all that special, but their presence has more to do with the relatively humble horsepower output of an A-Series (compared to, say, a drag racing engine) and with the priority Swift places on durability.

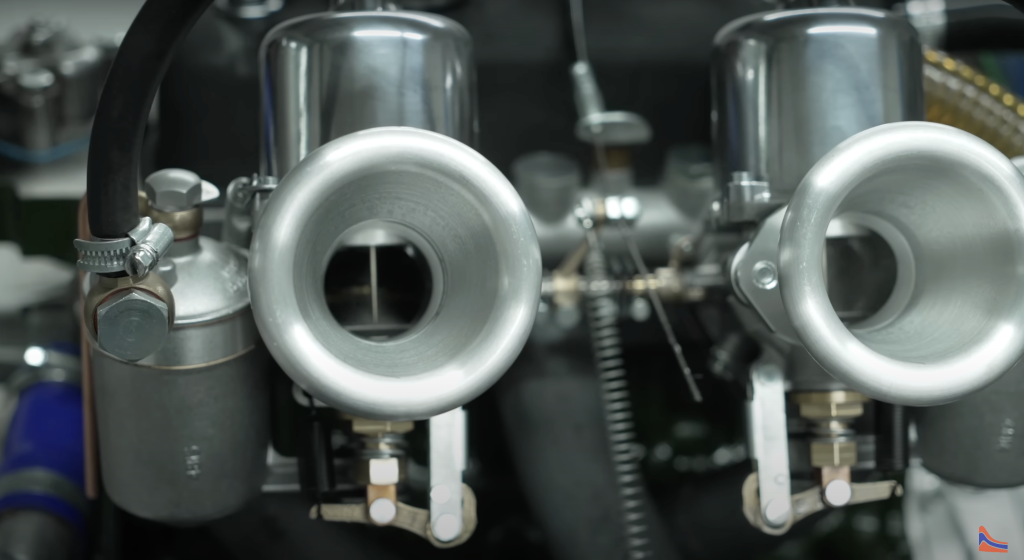

With a set of SU carbs and aluminium velocity stacks, this is a very pretty engine that can deliver everything a Mini driver could want when they start to squeeze on the throttle approaching the apex. Of course, for a spec racing engine, that exact amount of power is confirmed by an engine dynamometer before the engines are sent out the door. Though the design of these engines is pretty archaic, the goal is 100bhp per litre. And the sound is downright lovely at full chat. The view down those velocity stacks is pretty sweet, too. Makes me wish I had an A-series in the garage again.