Jesse Crosse started as a motoring hack in 1982, was launch editor of Performance Car magazine and signed up an unheard writer called Jeremy Clarkson. He now writes about automotive technology, and spends his time restoring a pair of fast Fords, a 1968 GT390 Mustang fastback, and the same Ford Sierra Cosworth long-term test car he ran while editor of Performance Car. Here he shares tech tips for the have-a-go DIY car enthusiast.

Exactly when the spark sparks, lights a fire in the combustion chamber and makes some power and noise is important because these things take time. The timing of exactly when that spark happens is important to how the engine runs, its performance, fuel consumption and crucially, its wellbeing.

On a modern classic with a distributorless electronic ignition system, a crank sensor usually does that job, sending a signal to the engine ECU (electronic control unit). By knowing the exact angle of the crank in degrees, the ECU software can fire the spark for each cylinder at the right time. That means there’s no setting of the ignition timing to do, as it’s controlled by the ECU software (known as an ignition map).

On older classics with a distributor, the timing needs to be set and checked periodically to make sure it’s still correct. As a reminder, a spark is triggered for each cylinder as the cam in it rotates at half crankshaft speed. Lobes on the cam open and close the contact breaker points and each time they open, a spark is triggered by the ignition coil. For more info on distributors and exactly how they work, check out an earlier column here.

Contact breaker points can be replaced by optical or Hall effect sensors, but the timing is still controlled by their position in relation to the distributor’s cam. For now though, we’ll stick with old-school contact breaker points because if they are incorrectly gapped, they too can affect timing to some extent. But before getting to the nitty-gritty of timing the ignition, why does it matter?

When fuel and air is ignited in a petrol engine it burns, and like a bonfire, that flame takes time to spread. Not much time, granted, just milliseconds, but it’s still a progressive process. Because events are happening in the engine very quickly, like the colossal speed of pistons travelling up and down the bores, then there may not be enough time for the fuel to burn and release its energy at the right point in the engine’s cycle.

For that reason, the fuel is usually ignited early to give it time to burn fully by the time the piston reaches the top of its stroke (top dead centre, or TDC) and begins its downwards power stroke. That’s what is meant by ignition timing, the precise point, relative to the position of the piston in the bore, when the fuel is ignited.

The position of the piston relates to the rotational angle of the crankshaft relative to TDC which is 0°. As the engine revs increase, so does the speed of the pistons and the time allowed for the fuel to burn reduces. To get over that, the mixture has to be ignited sooner the faster the engine goes. In engine speak, the ignition timing must be “advanced” as revs and load on the engine increase.

For that reason ignition timing on distributor-timed engines can be checked both statically with the engine turned off, and with it running. The starting point though, is static timing. Ignition timing settings listed in a workshop manual will usually give the amount of advance (before top dead centre, BTDC) static and with it running. So the Haynes Mini manual gives an early 998 Mini saloon setting as 5° BTDC static, and 8° BTDC at 600rpm with the vacuum advance pipe disconnected.

Automatic advance of the timing is controlled by two things. The first is a pair of bobweights in the distributor which rotate the distributor cam as the engine speeds up, meeting the heel of the points sooner and advancing the ignition. The second is a vacuum advance system consisting of a vacuum pipe connecting the distributor to the inlet manifold. As the throttle opens and load on the engine increases (it works harder), then pressure in the inlet manifold drops, which in turn advances the ignition timing at the distributor.

To check ignition timing, remove the spark plugs so the engine can be rotated easily and turn the engine in small amounts either through judicious shoving with the car in second or third gear or in neutral with a socket on the crank pulley. The aim is to align the timing mark on the crankshaft pulley with the corresponding number in degrees which is often stamped on an engine cover right next to it. In rare cases, the marks may be elsewhere. On early Minis, the marks are stamped on the flywheel behind a small inspection plate. Make sure the final alignment of the marks is done in the direction of the engine’s rotation to make sure all backlash between the crankshaft and distributor is taken up.

At this point, the contact breakers should be on the cusp of opening or already opened for number one spark plug. Undo the clamp fixing the distributor to the engine block and rotate the distributor body in the same direction as the cam to make sure the points are fully closed, then rotate it back again until they just open. That is the moment at which the spark will be generated.

To be accurate, with the ignition on, a multimeter across the points will drop to zero the instant they To be accurate, with the ignition on, a multimeter in parallel with the points connected between earth and the negative terminal of the coil, will give a reading the instant they open. If you don’t have one, a 12-volt bulb wired across the points will illuminate at the same instant. Another quick and easy method is to rotate the distributor with the ignition on, until the instant a spark jumps across the points.

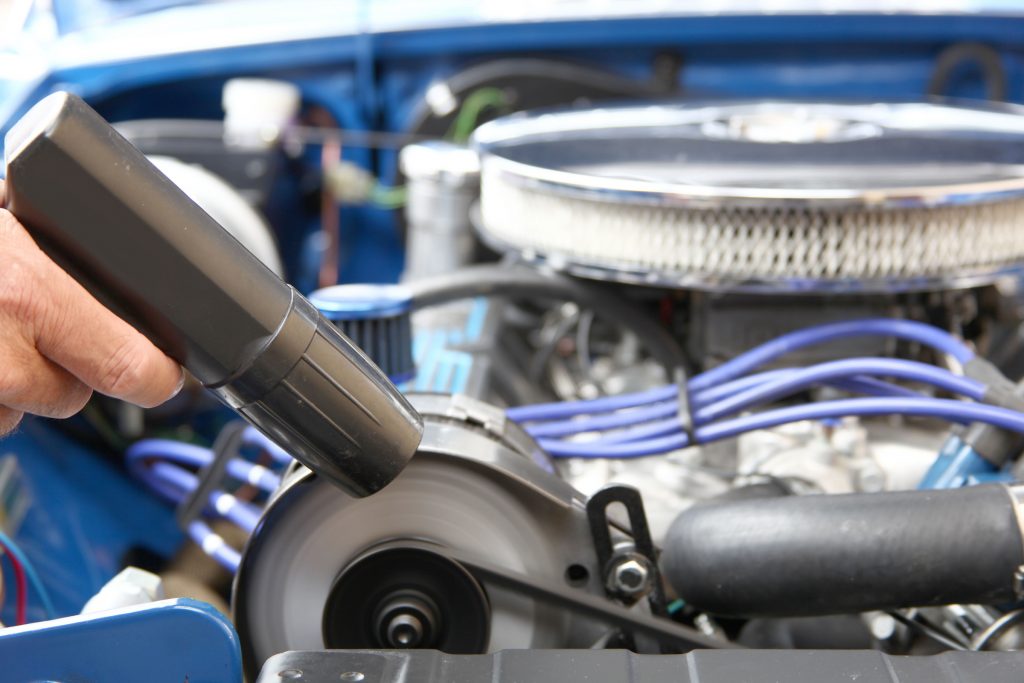

For testing with the engine running, you’ll need a stroboscopic timing light. Connected across the HT lead and spark plug on number one cylinder, the light will flash every time the plug sparks. Directing the light from the strobe light at the timing marks used for static timing, will reveal the advancing timing as the revs increase. Timing lights with built in rev counters make it easy to check at the revs listed in the manual.

If the distributor is fitted with points rather than an electronic ignition trigger, it’s important to check the points gap before you start because if it’s incorrect, that will also affect the timing. If the points gap is too small, the heel of the points will meet the cam lobe sooner, advancing the ignition slightly. Badly retarded timing causes overheating, back firing, poor performance and poor fuel consumption. Timing that’s too advanced can cause pinking (detonation), so it’s worth making a fairly regular check part of the routine.

Read more

Socket Set: Maintaining your car’s ignition system

Socket Set: Tappet adjustment on classic four-cylinder engines

Socket Set: Solving distributor problems

This statement in the article is completely false “As the throttle opens and load on the engine increases (it works harder), then pressure in the inlet manifold drops, which in turn advances the ignition timing at the distributor.” In fact, as the throttle opens and the load on the engine increases, the pressure in the inlet manifold increases (less vacuum), and the addition advance provided by the vacuum advance capsule decreases. Vacuum advance is highest when the throttle is engine is lightly loaded and at low throttle openings – the additional advance that it provides increases fuel economy without the risk of detonation.

David, thanks for taking the time to feedback. Bear in mind there are variations between UK and US classic cars, given the requirements around more stringent US emissions legislation back in the day. Below is a reply from Jesse Crosse, the author of the piece:

‘The purpose of the vacuum advance retard system is to advance the timing at part load. When a naturally-aspirated, throttled petrol engine is at part load (the throttle is partly open), a partial vacuum is created in the inlet tract, because the engine is drawing in air against a partially closed airway. Less fuel and air is being ingested and needs longer to burn efficiently, so the spark timing is advanced by the vacuum advance retard system. At full throttle, the airway is fully open, suction on the vacuum system disappears, it can no longer advance the timing and ‘returns to base,’ handing over timing advance to the distributor bobweights as the engine revs increase. At full throttle, the there’s a dense supply of fuel and air entering the engine. On tuned British classic engines, part load efficiency isn’t the objective but maximum performance is, so the vacuum advance retard is usually removed completely and competition distributors are not fitted with it.’